7 Notes For Hot Runner System Injection Molding

This article shows the 7 considerations for selecting and applying a hot runner system for injection molding. To eliminate or reduce the failure in use as much as possible, the following matters should be noted when selecting and applying a hot runner system for injection molding. 1. The choice of hot runner system heating method […]

11 Analyses of Injection Molding Process Parameters

After the read, you will learn about 11 and more Analyses of injection molding process parameters, and how to set the injection molding process parameters. The further development of injection molding equipment and the continuous improvement of product quality requirements have put forward higher requirements for the injection molding process. Correct selection of injection molding […]

Hot Runner Injection Molding Defects and Troubleshooting

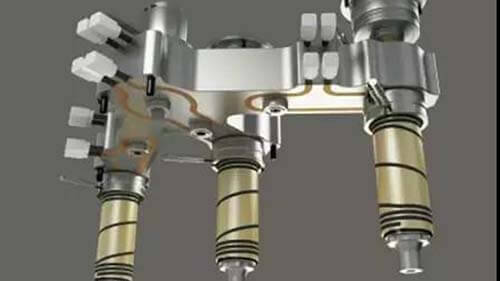

1. Why hot runner injection molding system is more important? Compared with ordinary runner molds, hot runner molds have the significant advantages of saving time and material, high efficiency, and stable quality, but once due to the use of easy-to-produce failure affects its widespread use. With the technical progress of the mold industry, hot runner […]

What Affects The Mold Opening?

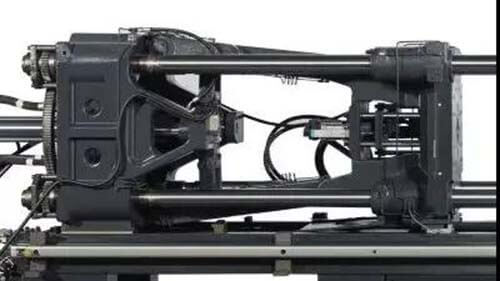

What is mold opening? Once the cooling phase has been completed, and the molding machine has been prepared for the next cycle, the mold is opened. In its most simple form, the mold opens, nothing exciting. However, more advanced molds may require core pulls, air blast control, or mold opening profiles. What are the factors […]

How to Increase the Brightness of ABS Plastic Products?

The following injection mold problems can be solved to increase the brightness of ABS plastic products. First, Injection mold issues for ABS plastic products 1. Poor processing of injection mold cavity of the ABS plastic products If the mold cavity has scars, microporous, wear, roughness, and other deficiencies will inevitably react to the plastic parts, […]

5 Heat-resistant ABS Injection Molding Attentions

What do I need to pay attention to in heat-resistant ABS injection molding? Reducing the internal stress of products is the key to heat-resistant ABS injection molding. In this article, we share the main points of processing for heat-resistant ABS injection molding from 5 aspects: mold design, material drying, molding temperature, holding pressure and time, […]

4 Causes of The Discoloration in Injection Molding

After the read, you will learn about the 4 causes and factors affecting discoloration in injection molding. What is the discoloration in injection molding? Discoloration in injection molding is defined as a disparity in the original color of the plastic. This injection molded part defect can arise from many sources, such as overheating, contamination, or […]

What is Multi-material Injection Molding?

Multi-material injection molding wiki Multi-material injection molding (MMM) is the process of molding two or more different materials into one plastic part simultaneously. As in traditional injection molding, multi-material injection molding uses materials at or near their melting point so that the semi-liquid (viscous) material can fill voids and cavities within a pre-machined mold, thus […]

What is the Role of Back Pressure?

What is back pressure? What does back pressure do? What is back pressure? Back pressure meaning Back Pressure, which refers to the pressure at the back end, is usually used to describe the pressure at the outlet or secondary side of a system’s discharge opposite to the flow direction (greater than the local atmospheric pressure). […]

4 Types of Cause of Burn Marks in Injection Moulding

After the read, you will learn about the common 4 types of a cause of burn marks in injection moulding products. Cause of burn marks in injection moulding 1 – Melt rupture When the melt is injected into the cavity at high speed and high pressure, it is easy to produce melt rupture. At this […]