What is mold opening?

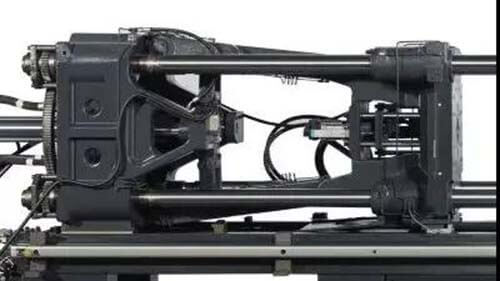

Once the cooling phase has been completed, and the molding machine has been prepared for the next cycle, the mold is opened. In its most simple form, the mold opens, nothing exciting. However, more advanced molds may require core pulls, air blast control, or mold opening profiles.

First, the speed and distance of the mold will affect the mold opening of the injection molding machine.

The distance the mold moves in mold opening and ejecting the part should be reduced to avoid wasting the moving time; of course, the mold must move enough to let the part out of the mold smoothly before the injection mold is closed again.

Therefore, the shorter the distance required to get the part out of the injection mold, the less time it will take. When the injection molding machine is in good condition, the transition from high-speed mold opening to low-speed mold ejection can be quite smooth.

The injection molding machine requires some maintenance to accomplish these speed changes, but these costs can be multiplied by the time saved through reduced molding time.

To achieve the least amount of injection mold travel time, adjust the deceleration limit switch so that the mold does not touch or damage the part too much during pre-exit, and optimize the high-speed section of the stroke.

Second, proper cyclical maintenance will affect the mold opening of the injection molding machine.

Proper cyclical maintenance to ensure this deceleration can be repeated every time.

Generating clamping pressure time is another delay in the overall mold opening time. This time may be affected by mechanical wear, and tear and hydraulic valve failure so that periodic mechanical maintenance can maintain good operating conditions.

Mold opening cautions

Shorten the die mold opening stroke to the minimum necessary for the part and runner dislodgement.

Eliminate any factors that make ejection difficult, like flying edges (phi) around the ejector pin.

Shortening the ejector stroke to the minimum necessary.

Using the fastest possible opening and closing speeds while aborting and closing properly and slowly to prevent damage to the injection mold.

To look for all the stops in the closing of the mold and in the generation of the clamping pressure, which indicates mechanical or hydraulic valve failures.

A large amount of activity in the injection mold for loading inserts also increases mold opening time. A little consideration of the product design (reduction of backlash) tends to automate or semi-automate the ejector action.

If the delay is caused by mold wear and tear, the mold should be repaired to reduce the delay.

Developing good operating habits for injection molding machines to improve machine life and product safety is very beneficial.

Analysis of the 3 aspects of injection molding machine failure to open the mold

In the injection molding machine maintenance, often encounter the failure of the inability to the mold opening. Unable to open the mold is mainly divided into pressure without action, pressure with action, no pressure without action three kinds of failure phenomena.

1. No action with pressure

First look at the output board to open the molded valve display light, if the light, the computer output is normal, the computer to open the molded valve line problems, the simplest way is a person with a small electric pen top open the molded valve, another person to open the mold action, if the top can open the mold smoothly, is to confirm the route of the problem, pull a new line on the solution (circuit problems).

2. There is pressure to open the mold action, but cannot open the mold

It means that the output board is normal, and the circuit from the output board to the valve is normal. There are four cases here.

Firstly: the clamping screw of the clamping cylinder piston is loose, causing the screw to pull hair in the cylinder, such as the piston rod being stuck.

Secondly: in mechanical anti-lock, the best way, disassemble the clamping oil pipe with a jack operation so that the machinery will not cause damage.

Thirdly: the machine twist caused by the pull cannot be caused (such as a jagged edge burned to death, etc.).

Fourthly: caused by interference (oil interference and circuit interference), such as spool clamping, and at the same time act mold opening situation, the oil pump oil supply cannot reach the pressure and flow required to the mold opening since cannot mold opening;

Another kind of interference is the interference of the circuit, such as the line of the mold opening and clamping wires being connected because the mold opening valve and clamping valve work simultaneously, with about 20 kg pressure, and also cannot open the mold.

3. No pressure no action

Check the computer output board is normal, there is pressure speed, the mold opening valve has output, and the computer home page is displayed. In this case, we check other actions, such as the shooting table and shooting seat, and found them to be normal, indicating that this phenomenon belongs to the mold opening unity.

General check for a person to open the mold action, another person with a multimeter, measuring whether the mold opening valve coil voltage of about 22 – 30V. If there is, we will temporarily pull the plug out of the open mold valve coil and open the mold action. If there is pressure and no action, we disassemble the mold cylinder this time. There must be a piston from the piston rod loose inside.

Because the injection molding machine oil circuit is largely the same, opening the mold, there is this situation, and other actions will also be so. Repair machine is important to summarize. From this failure, we found that the repair machine is simple and complex, but roughly from the circuit, hydraulic, oil, and mechanical four aspects.

We generally want to pay attention to the order of its troubleshooting, from simple to complex, that is, circuit, hydraulic, oil, and mechanical. If the inspection order is not appropriate, repair is laborious and time-consuming.

Besides the What Affects The Mold Opening article, you may also be interested in the below.

6 Common Plastic Injection Molding Process Techniques

What is Multi-material Injection Molding?

How to Increase the Brightness of ABS Plastic Products?

Hot Runner Injection Molding Defects and Troubleshooting

11 Analyses of Injection Molding Process Parameters

17 Injection Molding Problems And Solutions