7 Parameters of Engineering Plastic Material Properties

About engineering plastic material properties, 7 parameters you must understand. Engineering plastics have been used daily, mainly as engineering materials, instead of metal for manufacturing machine parts. In the automotive industry, automobiles’ lightweight, safe, and environmentally protection have been realized by replacing steel with plastic. In the selection of engineering plastics, material engineers must consider […]

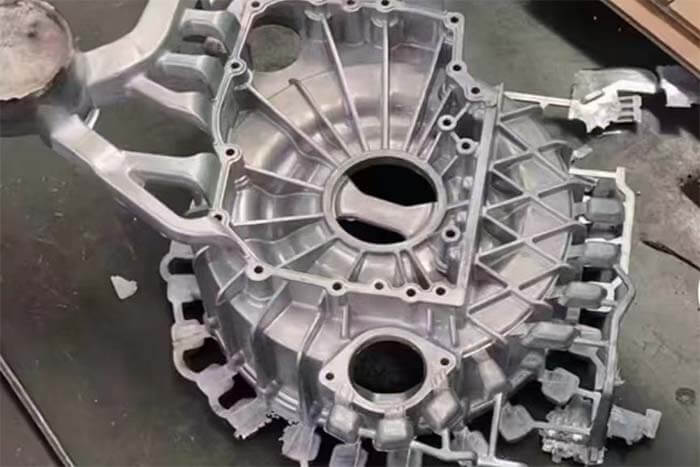

What are the Reasons for the Difficulties in Manufacturing Injection Molds?

What are the causes of the difficulties in manufacturing injection molds, do you know? The cavity and core are three-dimensional surfaces, which makes the difficulties in manufacturing injection molds The cavities and cores directly shape plastic parts’ external and internal shapes, and these complex three-dimensional surfaces are difficult to process, especially the blind holes in […]

How to Solve the High-gloss Injection Molded Parts Problem?

What are the high-gloss injection molded parts? High-gloss injection molded parts products are indeed a more difficult for injection molding enterprises to cope with because they cannot hide external defects. Even the dust in the workshop can cause different degrees of defective products, such as trachoma, pockmark, staining, etc., so the environment is also affecting […]

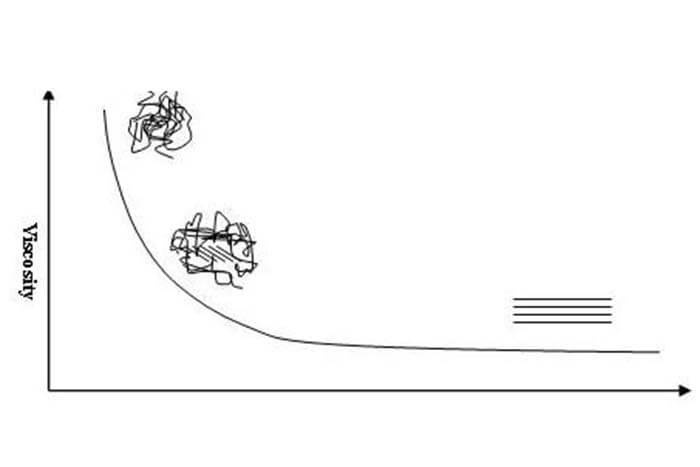

6 Aspects of Scientific Injection Molding Theory

This article comprehensively explains scientific injection molding theory from 6 aspects. Here we go! Injection molding theory of viscosity of injection molding Newtonian fluid is a fluid whose viscosity is not affected by the shear rate applied to it. When the shear changes, the viscosity remains constant. Non-Newtonian fluid is a fluid whose viscosity varies […]

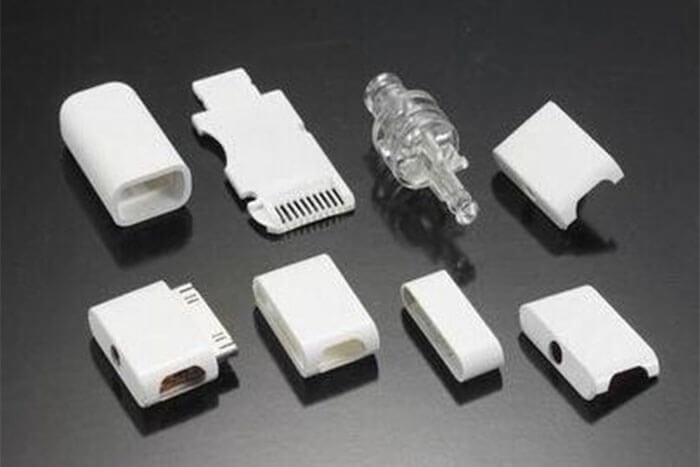

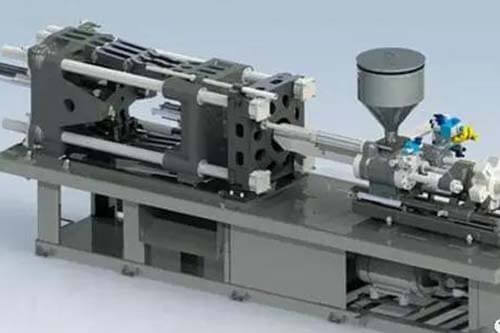

6 Common Plastic Injection Molding Process Techniques

The 6 common plastic injection molding process techniques for plastic products for home appliances are mainly injection molding, extrusion, thermoforming, hollow molding, lamination molding, compression molding, transfer molding, foam molding, embedded casting, sealing casting, etc., of which injection molding is the main. In recent years, some new plastic injection molding process technologies and equipment have […]

How to Reduce the Irregular Flow of Plastic Melting?

This article discusses how to reduce the irregular flow of plastic melting in the injection mold cavity. What is the flow of plastic melting in the mold cavity? When the melt is injected into the mold cavity, it first forms a thin case on the injection mold cavity wall. When the subsequent melt squeezes this […]

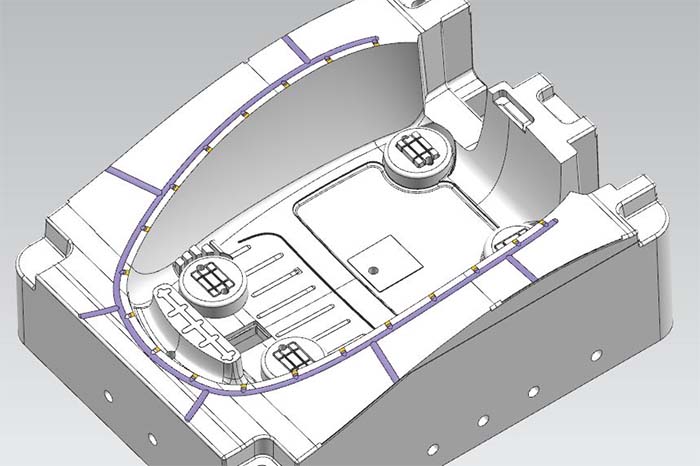

What is the Function of Mold Venting?

What is the role of mold venting? There are two main functions of the mold venting slot: First, to remove the air from the mold cavity when injecting molten material; Second, to remove all kinds of gases generated by the material during the heating process. The more thin-walled products, the farther away from the gate, […]

Multi-stage Injection Molding Speed Segmentation Principles

What is the multi-stage injection molding speed segmentation? The basis for setting the multi-stage injection molding speed segmentation must consider the mold’s geometry, other flow restrictions, and instability factors. The multi-stage injection molding speed must be set with a clear understanding of the injection molding process and material knowledge. Otherwise, the product quality will be […]

The Injection Speed in Injection Molding

What are the relationship between injection speed in injection molding and the quality of injection molded parts? The relationship between injection speed in injection molding and the quality of injection molded parts is a close relationship between injection speed in injection molding and product quality, making it a key parameter for injection molding. By determining […]

Handle Shell 2-Color Injection Molding Case

The case of 2-color injection molding for the handle shell requires two sets of core cavities of the dynamic mold that cannot be the same, how to solve it? How to solve this problem? The moving mold adopts movable inserts (the middle plate mold). Its working principle is: after the injection molding machine finishes the […]