Description

What is a Forged Closed-end Mold Clamp For Injection Molding?

The Forged Closed-end Mold Clamp For Injection Molding is a closed-toe mold clamp type with forged medium carbon steel adjustable mold clamp used for injection molding, milling, drilling, sheet metal presses, shaper, boring machine industry, etc.

DGMF Mold Clamps Co., Ltd offers the Adjustable Forged Closed-end Mold Clamp For Injection Molding, which manufactures the adjustable closed-end mold clamp, The Adjustable Closed-end Mold Clamp with M12, M16, M20, and M24 sizes.

Contact us for more mold clamp parts, specifications, and prices.

Mold clamp bodies, mold clamp bolts, mold clamp nuts, and mold clamp washers are available at DGMF Mold Clamps Co., Ltd. They can be purchased as complete sets or single components.

What is the Forged Closed-end Mold Clamp For Injection Molding feature?

Mold Clamp Material: Medium carbon steel

Mold Clamp Finish: Black color and Blue color

The mold Clamp is forged and hardened.

The mold clamp assembly is adjustable.

Anti-slip mold clamp.

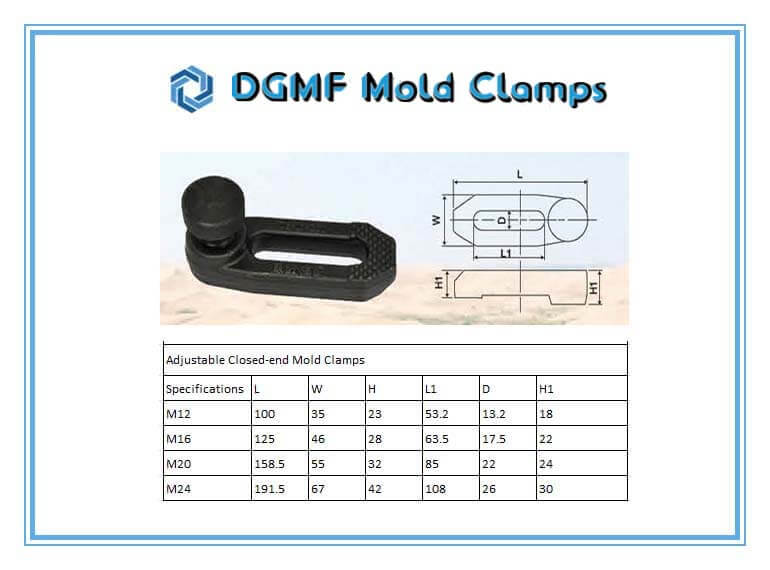

Forged Closed-end Mold Clamp For Injection Molding Specifications

| Forged Closed-end Mold Clamp For Injection Molding | |||||

| Specifications | L | W | H | L1 | D |

| DGMF-MOLD-CLAMPS-047-M12 | 100 | 35 | 23 | 53.2 | 13.2 |

| DGMF-MOLD-CLAMPS-047-M16 | 125 | 46 | 28 | 63.5 | 17.5 |

| DGMF-MOLD-CLAMPS-047-M20 | 158.5 | 55 | 32 | 85 | 22 |

| DGMF-MOLD-CLAMPS-047-M24 | 191.5 | 67 | 42 | 108 | 26 |

Forged Closed-end Mold Clamp views

Forged Closed-end Mold Clamp Assembly Types

1PC Forged closed-end adjustable mold clamp body

1PC T bolt

1PC Flange nut

Or clamping bolts, nuts, and washers are choosable.

1PC Forged closed-end adjustable mold clamp body

1PC Clamping stud bolt

1PC Hex nut

Or clamping bolts with a spanner, T nuts, and washers are choosable.

DGMF Mold Clamps Co., Ltd manufactures high-quality mold clamps such as quick-change, closed-end, open-end, universal, and U-shape mold clamps, easy mold clamps, gooseneck clamps, stamping die clamps, milling machine clamps, plain clamps, mold base clamps, and mold clamp parts, etc.

Extra-large adjusting screw assemblies.

Heavy-duty clamping studs/studs with a spanner

High strength, Hex head clamping screws

High-strength, T-slot bolts

Heavy-duty hex nuts for T-slot bolts

Heavy-duty flange nuts

Round mold clamp washers

Extra-large round mold clamp washers

Extra-large no-twist rectangular mold clamp washers

You can buy the mold clamp assembly set or mold clamp components individually.

Contact us for more clamping element details you need.

Reviews

There are no reviews yet.