This article describes the Stamping Die Design Guidelines, the taboos of the three main stamping die design processes, namely blanking, bending and drawing, and the material considerations for stamping die.

What is stamping?

What is stamping die design?

Stamping die design is the preliminary phase in stamping tool and die making and is carried out as soon as the component design is finished. During the design phase, the necessary manufacturing methods, as well as the sequence and number of production steps, are established in a processing plan.

Taboos in the stamping die design guidelines

This article lists 71 taboos in the stamping die design guidelines, how many do you know?

Blanking

Blanking is a stamping process that uses a punching die to separate part of the material or process piece from another part of the material, work (process) piece or scrap. Blanking is the general term for the separation processes of shearing, cropping, punching, notching, grooving, cutting, chiselling, edge cutting, tongue cutting, cutting and repairing.

A stamping method for separating parts or blanks of the required shape and size from a sheet. Blanking is the use of the die’s edge to deform and separate the sheet along a certain contour line. Stamping accounts for the largest proportion of press production. In the blanking process, the sheet itself is not plastically deformed, except for the metal near the shear contour line, so the part processed by the flat blanking process is still a flat shape.

Blanking process taboos of stamping die design guidelines

1. The blanking process should not be too complex

In order to facilitate the waste and no waste row sample, the shape of the blanking part should not be too complex, and should strive to be simple, and symmetrical; in the case of permission, the blanking part can be designed into the shape of less, no waste row sample.

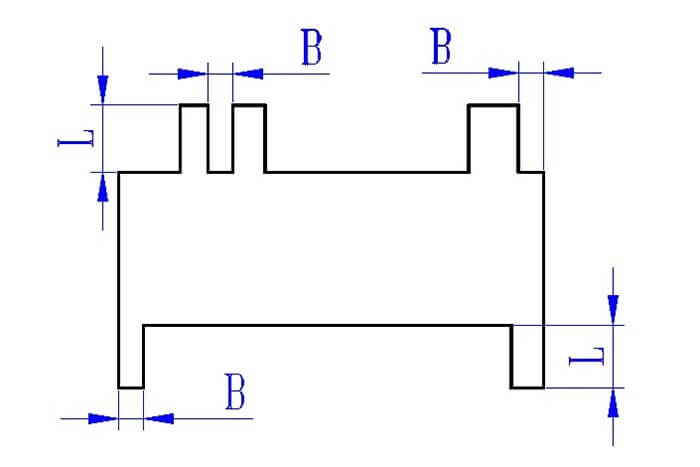

2. The projection or concave part of the blanking should not be too small

The cantilevered and recessed slots of the blanking should not be too small, as this will reduce the life of the die and the quality of the workpiece.

In general, the width B should not be less than 1.5 times the material thickness t. When the workpiece material is brass, aluminium or mild steel, the cantilever and slot width should be more than 1.3 times the material thickness; When the workpiece material is high carbon steel, its width should not be less than 1.9 times the material thickness.

3. Blanked parts should not have sharp corners

The connection of each straight or curved line of the blanked part should not be made with sharp corners, but with appropriate rounded corners. When blanking in one process, the corners should be designed with large rounded corners as far as possible.

If the blanking part has sharp corners, not only does it make the manufacture of the blanking die difficult, but the die is also easily damaged. Only in the case of less scrap-free platings or inlay die constructions are sharp clear corners of the workpiece allowed.

4. The size of the hole in the punched part should not be too small

When punching holes, the size of the hole should not be too small due to the limitations of the strength and stability of the die.

The value is related to the shape of the hole, the properties of the material and the thickness of the material.

When the material is brass, pure aluminium or zinc, the hole size should not be less than 0.5 to 0.8 times the material thickness;

When the material is mild steel, the hole size should not be less than 0.7 to 1 times the material thickness;

When the material is high carbon steel, the hole size should not be greater than 1.1 to 1.5 times the material thickness.

5. The distance between the holes of the punched parts should not be too small

The distance between the holes and the edges of the punched parts is limited by the strength of the die and the quality of the punched parts, and the value is not small.

Generally, it should be more than 2 times the thickness of the material and not less than 3-4 mm. If necessary, 1 to 1.5 times the thickness of the material.

6. Bending or deep-drawing parts of the hole wall distance should not be too small

Bending or deep drawing parts on the punching, its hole edge and the workpiece between the straight wall distance can not be too small.

Generally greater than the radius of the wall end rounding plus half of the material thickness. If the distance is too small, the hole edge will enter the rounded part of the bottom of the workpiece, and the die will be broken by the horizontal steak force when blanking.

7. The clearance between the blanking die and the concave die should not be too large or too small

The clearance between the convex and concave dies has a great influence on the quality of the cross-section of the blanked part. If the gap is too small, the cracks in the die edge will be staggered outwards and the material between the upper and lower cracks will be sheared for the second time, and a second bright band and interlayer will be formed on the shear surface.

If the gap is too large, the cracks in the die will be staggered inwards, the material will be stretched, the bright band will be small, the burr, the collapse angle, the slope will increase and sometimes there will be a depression. The gap value can be selected according to the following formula.

Z=mt.

The Z is the double-sided gap.

t is the material thickness.

m is the coefficient, low carbon steel and brass to take 0.08 ~ 0.1, medium carbon steel to take 0.12 ~ 0.14, and aluminium, and pure copper to take 0.04.

8. The blank gap should not be on the concave die

The size of the large end of the blanking is equal to the size of the concave die and is measured by taking the size of the large end of the blanking as a reference. Therefore, the gap should be taken in the direction that reduces the size of the convex die, i.e.

Dp = Dd – Z

The Dp is the nominal size of the convex die.

Dd is the nominal size of the concave die.

Z is the double-sided blanking gap.

9. Blanking clearance should not be taken in the convex die

The size of the small end of the blanking is equal to the size of the die. When measuring, the small end of the blanking is taken as a reference. Therefore, the hole is blanked using the size of the convex die as a reference and the clearance is taken in the direction of the increase in the size of the concave die, i.e.

dd=dp+Z

The dd is the nominal size of the concave die for blanking.

dp is the nominal size of the blanking die.

Z is the double-sided blanking gap.

10. The dimensions and tolerances of the blanking die should not be considered before the convex die

As the blanking is dimensioned on the large end of the workpiece, it is also equal to the size of the concave die. Therefore, the size of the concave die should be determined first according to the blanking workpiece and then the size of the convex die according to the clearance value.

Considering that the wear of the edge will gradually increase the size of the blanking, in order to increase the service life of the blanking die, the nominal size of the concave die should be taken as the smaller size of the workpiece size tolerance range and the clearance should be taken as the minimum reasonable clearance. The size of the working part of the convex and concave die can be determined according to the following formula.

Dd + δd 0 = (Dw – xΔ) + δd 0

Dp 0 – δp = (dd – Zmin) 0 – δp

The Dd is the nominal size of the edge of the blanking die.

Dp is the nominal size of the cutting edge of the blanking die.

Dp is the nominal size of the outer diameter of the blanking part

Zmin is the minimum reasonable double-sided clearance.

Δ is the manufacturing tolerance of the blanking part.

x is the correction factor, generally taken to be 0.5 to 0.75.

δd is the manufacturing tolerance of the concave die, taken as (0.25 to 0.35)Δ.

δp is the manufacturing tolerance of the convex die, taken as (0.25-0.35)Δ.

11. The dimensions and tolerances of the blanking die should not be considered before the dimensions of the concave die

As the small end of the blanking is used as a reference for dimensioning, the size of the die should be determined first by the size of the workpiece aperture and then the size of the concave die by the clearance. Edge wear will reduce the size of the blanked hole.

To increase the life of the die, the die size should be larger size within the tolerance range of the workpiece bore size. The clearance is also the minimum reasonable clearance. The size of the working part of the convex and concave die can be determined according to the following formula.

dp 0 – δp = (dw + xΔ) 0 – δp

dd +δd 0=(dp+Zmin)+δd 0

The dp is the nominal size of the blanking die edge.

dd is the nominal size of the die edge of the blanked concave die.

dw is the nominal size of the workpiece bore.

The other symbols are the same as in the previous paragraph.

12. The layout of the blanked part should not leave too much waste

In order to improve the material utilisation rate, it is important to have a reasonable pattern of blanked parts. Round parts are arranged in single rows, parallel double rows, cross double rows and multiple rows.

The more rows, the higher the material utilisation rate, but the number of rows by the process and mould manufacturing restrictions, should not be too much, non-round parts of the row sample, to be divided into the straight, oblique row, straight rows, mixed row, more and row, etc.

If the main technical requirements of the workpiece are not affected and with the consent of the product designer, the structure of the workpiece shape can be changed to be suitable for less waste-free folding row samples in order to save material.

13. The selection of a blanking press should not be based solely on the area of the die

The selection of a blanking press is mainly based on the blanking force.

The main factors affecting the blanking force are the thickness and mechanical properties of the material, the length of the perimeter of the blanked part, the size of the die clearance and the sharpness of the cutting edge.

The blanking force P (N) for a general flat-edged blanking die is calculated according to the following formula.

P = L tτ

τ= 0.8σb = 0.28HB

The τ is the shear strength (MPa).

L is the perimeter length of the blank (mm).

t is the thickness of the material (mm).

σb is the tensile strength of the material (MPa).

14. The selection of a blanking press should not only take into account the blanking force

The selection of the blanking press must be combined with the blanking force and the area of the die. When the area of the part to be blanked is small and the punching force is large, the die structure can be considered to reduce the blanking force.

The main methods of reducing blanking force are: bevelled edge blanking, stepped convex die blanking, part division blanking and heating blanking.

The bevelled edge blanking method is to make the edge of the convex die (punching) or concave die (blanking) inclined at an angle to its axis. The edge is gradually cut in during punching to reduce the punching force.

The stepped die blanking method involves arranging multiple dies in a stepped pattern and cutting into them one by one to reduce the blanking force.

15. The die shank must not deviate from the centre of pressure of the die

In order for the die to work correctly and smoothly, the shank of the die must not deviate from the centre of pressure of the die, as this will accelerate the wear of the guide mechanism. This is particularly true for open dies without guides.

16. Non-metallic materials such as felt, leather, etc. Which cannot be used with flat convex dies

Non-metallic materials such as felt, leather, rubber sheets, asbestos rubber sheets, paper, cotton fabrics, etc. cannot be blanked or dropped using the usual flat-convex dies, but are often used with sharp-edged convex dies. The sharp edge angle is approximately 10° to 30°.

To prevent dulling and chipping of the edge, the material to be blanked is padded with hardwood, cardboard or polyurethane rubber. As the sharp-edged convex die is easily damaged, its assembly and disassembly, manufacture and maintenance and convenience should be taken into account.

17. Blanking and cutting of tubes cannot be done with normal blanking dies

Blanking and cutting of tubes is highly productive with small burrs in the cut. However, in order to prevent the tube wall from being flattened, a normal blanking die or shear cannot be used, but a convex die with a plate tip should be used.

For mass production, the double blanking method is used. The tube is first cut horizontally with a planing knife and then cut into the cut with a movable thin blade. Both sides of the cut are firmly clamped with a combination die. In order to keep the tube in a constant state of compression during blanking, a movable compression plate is provided on the die.

18. High-speed blanking should not be done with normal blanking dies

When the number of press strokes reaches 500 strokes/min or more, the imbalance in the operation of the press increases significantly and the vibration and inertia forces in the die are high.

Therefore, effective anti-loosening measures should be adopted, attempts should be made to reduce the weight of the upper die, equipment with good rigidity and high precision should be used to improve the accuracy and life of the die, and the die clearance should be increased appropriately.

The upper/lower die is double-guided, except for the four ball-guiding devices, and the fixed plate of the convex die, the unloading plate and the concave die are about 10% larger than the ordinary blanking.

19. High-precision blanked parts should not be made with normal blanking dies

The workpiece obtained with a general blanking die has collapsed corners, fracture zones and burrs on the shear surface, as well as an obvious taper, with a surface roughness of Ra 6.3 to 12.5 μm.

For higher demands on the quality and dimensional accuracy of the cross-section of the blanked part, trimming, negative gap blanking, up-and-down blanking and simultaneous shearing and squeezing can be used. The dressing is the use of a dressing die to scrape a thin layer of chips along the outer edge of the blank or hole wall to obtain a smooth and vertical section and accurate dimensions.

The essence of the negative gap blanking method is a compound punching-trimming process. The up-and-down blanking method uses two convex dies to blank the workpiece twice, from the top and the bottom, to obtain two bright bands, top and bottom, and to remove burrs.

20. Precision blanking does not allow the workpiece material to tear during the blanking process

The following measures are taken in order to prevent the material from tearing during the blanking process and to ensure that the plastic deformation process is carried out: the V-shaped crimp ring is used to press the material, combined with a small gap to keep the material perpendicular to the blanking direction, avoiding bending and warping and generating tensile stresses in the deformation zone, which constitute the conditions for plastic shearing.

The crimping force and counter pressure are used to increase the hydrostatic pressure of the material in the deformation zone in order to increase the plasticity of the material. If necessary, rounding the die or die edge to reduce the stress concentration at the edge and avoid or retard the formation of cracks.

21. The crimping force for precision blanking should not be too small

In order to prevent the tearing of the section during precision blanking, it is necessary to use the crimping force to increase the hydrostatic pressure of the material in the deformation zone. The crimping force (N) is calculated according to the following formula:

P=f L2hσb

The L is the length of the outer periphery of the workpiece (mm).

h is the V-shaped tooth height (mm).

σb is the tensile strength of the material (MPa).

f is the coefficient, check the following table.

σb / MPa | 200 | 300 | 400 | 600 | 800 |

f | 1.2 | 2.4 | 1.6 | 1.9 | 2.2 |

22. The counterpressure of precision blanking cannot be sized

Counterpressure is an important factor affecting the quality of the fine-blanked part. Too little counterpressure will affect the dimensional accuracy of the workpiece, the flatness, the collapse angle and the quality of the shear surface of the hole.

However, too much counterpressure will increase the load on the die and reduce its life of the die. The counter pressure (N) is calculated according to the following formula.

P=pF or P=20%P

The F is the open surface area of the workpiece (mm2).

p is the unit counterpressure, generally taken as 20 to 70 MPa.

P is the blanking force (N).

23. The clearance between the convex and concave dies for precision blanking cannot be greatly reduced

A small gap is the main characteristic of a fine blanking die. The size of the gap and its uniformity along the perimeter of the edge directly affect the quality of the shear surface of the fine-blanked part.

Fine blanking clearance depends mainly on the thickness of the material, but also on the contour of the blank and the material of the workpiece.

The gap between the convex and concave die is generally 1% to 2% of the material thickness. If the gap is too large, the shear end layer flakes off and the shear surface is corrugated.

Material thickness t /mm | Shape | Inner shape (hole, diameter d) | ||

d<t | d=(1~5) t | d>5t | ||

0.5 | 2.5 | 2.0 | 1.0 | |

1 | 2.5 | 2.0 | 1.0 | |

2 | 2.5 | 1.0 | 0.5 | |

3 | 2.0 | 1.0 | 0.5 | |

4 | 1.0 | 1.7 | 0.75 | 0.5 |

6 | 1.7 | 0.5 | 0.5 | |

10 | 1.5 | 0.5 | 0.5 | |

15 | 1.0 | 0.5 | 0.5 | |

24. Highly demanding blanking dies should not be unguided

Simple blanking dies without guides or guides are only suitable for less demanding, simple shapes and small batches of blanked parts. This type of die is troublesome to install and adjust, has a low die life, poor accuracy of the blanked parts and is not safe to operate.

In the case of column type dies, the upper and lower dies are guided by a sliding fit of guide posts and guide bushings, which is highly reliable, has high guiding accuracy, long life and is easy to use and install.

25. Continuous dies should not be used without positioning devices such as stop pins and guide pins

To ensure the quality of the workpiece, the accurate positioning of the material must be solved. Commonly used positioning devices are fixed stop pins, guide pins and side cutters.

When blanking, the fixed stopper pin is used for initial positioning, and the guide pin, which is mounted on the end face of the die, is used to ensure the correct positioning of the bar when the material is dropped.

The side cutter is used to control the feed distance of the strip. The width of the front and rear guides of the side cutter is not equal, and the strip can only be fed one step after the side cutter has cut off the edge of the material with a length equal to the step.

26. Small-diameter blanking dies should not be simple cylindrical

To avoid stress concentration and to ensure strength and stiffness, small-diameter blanking dies should not be made in a simple cylindrical shape, but in a stepped form with a smooth transition or in a sheath structure.

The sheathing improves the resistance to longitudinal bending and saves die material. Otherwise, the small diameter punching die will break easily when working.

27. Blanking dies should not be made with straight wall cavities

In order to workpiece or waste easy to fall, a concave die cavity can not be made into a straight wall, but to be made into a cone, column orifice cone or column orifice step shape. The pillar orifice is easier to manufacture, has high edge strength and the wall size remains the same after resharpening.

When blanking, if the inner wall of the die is straight, the workpiece or scrap will be stuck in the inner cavity and too much will accumulate to destroy the die.

28. Blanking dies should not ignore the centre of pressure

The point of action of the full combined force of the blanking force is the centre of pressure of the die. If the centre of pressure is not on the die shank axis, the slide will be subjected to eccentric loads, resulting in abnormal wear on the slide guide and the die, reducing the die life and even damaging the die.

The centre of pressure of the mould is usually determined by the method of finding the point of action of the combined forces of the parallel force systems.

For concave moulds with multiple holes, the centre of gravity of each hole plan is first calculated separately, and then the co-ordinates of the point of action of the combined forces are found according to the principle that “the algebraic sum of the moments of the component forces on an axis is equal to the moment of the combined forces on that axis”.

29. The complex shape of the part and the sharp corners of the concave mould should not be made into an integral type

To reduce the deformation of the mould during heat treatment, to prevent cracks from stress concentration at the sharp corners, and to simplify the manufacture and maintenance of moulds, concave moulds with complex shapes and sharp corners should not be used as a whole and can be made into a block assembled concave mould.

Bending

The bending process is to bend the plate, bar, tube, or profile into a certain shape and the angle parts of the forming method are one of the common processing methods in sheet metal stamping.

In the production of bent parts in many shapes, such as V-shaped parts, U-shaped parts, cap-shaped parts, arc-shaped parts, etc. These parts can be bent on the press with a die, but also with a special bending machine for bending or roll bending.

1. The corner radius of the bent part should not be too large

Workpiece bending, in addition to plastic deformation, must be accompanied by elastic deformation, resulting in the rebound. Therefore, the corner of the bent part should not be too large. Otherwise, it is difficult to ensure accuracy.

2. The corner radius of the bent part should not be too small

Bending the radius of the corner should not be too small, otherwise, the outer layer of fibers will produce pulling crack damage.

For mild steel, the minimum bending angle of about 1.0 times the thickness of the plate;

For brass and aluminum, the minimum bending angle of about 0.6 times the thickness of the plate;

For carbon steel, the minimum bending angle of about 1.5 times the thickness of the plate.

3. The height of the straight edge of the bent part should not be too small

To ensure the quality of workpiece bending, bending straight edge height h should not be too small, and must be greater than or equal to the minimum bending edge height hmin.

h ≥ hmin = +2t

The r for the bending angle.

t for the bending plate thickness.

4. The Bending hole edge distance should not be too small

Bending holes in the blank, the hole edge distance should not be too small. If the hole position is too close to the bending area, the shape of the hole will change when bending. The distance l from the hole edge to the bending edge should conform to the following formula.

When t<2, l≥r+t

When t ≥ 2, l ≥ r + 2t

The r is the bending angle.

t for the bending plate thickness.

5. Bending shape and size of the symmetry should not be too big a difference

In order to prevent deformation, the height difference between the bending parts should not be too large.

The shape and size of the bent part should be as symmetrical as possible, otherwise, it will produce a distorted distortion at the small end. If such a result is difficult to improve in design, it must be ensured that:

h>r+2t

The h is the height of the small side.

r is the bending fillet.

t is the thickness of the bent part plate.

6. Local bending edge should not ignore blanking the unloading hole slot

In the local bending of a section of the edge, in order to mind the junction due to stress concentration and tearing, should not ignore the first blanking unloading hole, groove cutting, or bending line displacement a certain distance.

7. Narrow edge bending should not ignore the process of cut

In narrow-side bending, the deformation zone of the cross-sectional shape will be distorted, that is, the width of the inner surface becomes wider, and the width of the outer surface becomes narrower. This is particularly noticeable when the plate width b < 3t (t is the plate thickness).

If the width of the bent parts b high precision requirements, do not allow bulging phenomenon, should not ignore the bending line in advance to make process cuts.

8. Bending process can not ignore the rebound

Bending plastic deformation and elastic deformation at the same time. When the external load is removed, the elastic deformation disappears, resulting in a rebound. Rebound value and material properties, the relative bending radius r / t, bending angle, and other factors.

The higher the yield point σs of the material, the smaller the modulus of elasticity E, the smaller the r/t, the larger the bending angle, the greater the rebound. In order to ensure the accuracy of the workpiece, bending can not ignore the rebound.

Can repair the mold, the use of different parts of the rebound direction, and the local increase in the triangular rib method to reduce rebound, can also be used to reduce the rebound of the concave die structure of the swing block.

9. Bending a large radius’ workpiece can not use the ordinary bending method

For the bending radius of a large part, can not use the ordinary bending method. Otherwise, due to its large elastic deformation can not get the required shape and size. In this case, the method of pull bending is available.

In the sheet bending before adding an axial tension, the data so that the stress within the blank section is slightly greater than the yield point of the material, and then bend in tension at the same time.

10. Bending of complex-shaped parts can not be bent in one time

The complex shape of the bending parts, can not be bent into a bending, and the need for multiple bending and forming.

The principle of work sequence arrangement is to bend the outer corner. After the second bending can not affect the previous bending part of the deformation. The number of bending time can be two, three, or even more.

11. Bending edge should not have a notch

The edge part of the notch bending parts, if the blank will be notched out, bending will appear forked, serious when it can not be formed. This must be left in the gap at the connection belt, to be bent into shape and then the connection belt removed.

12. Bending die structure can not ignore the blank offset

In the bending process, the offset is an important factor affecting the accuracy of the workpiece, so before the start of bending, the blank should be part of a reliable fixed in a part of the mold to prevent bending offset.

Holes in the part should be used for positioning as far as possible. If there are no holes available in the part, then process holes can be considered for positioning.

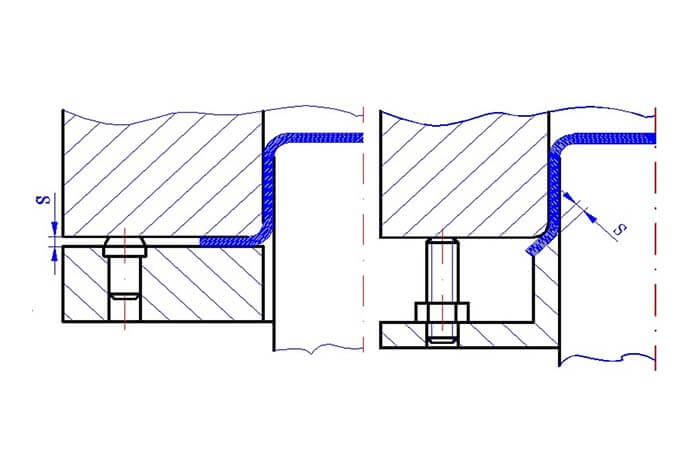

13. Bending die construction should not result in large local thinning and scratching of the material in the closed die

The bending die should take care to bend only in the position of the bending line defined by the part during the closing process. The blank should not be subjected to large localized thinning and scratching.

When bending with the structure shown on the left, the position of the bend line at the outer corner C changes during the bending process, first at point B and finally at point C so that the outer corner of the part is not shaped correctly and the straight arm part is thinned.

14. The structure of the mould should not hinder and prevent the rotation and movement of the blank during the closing process

The structure of the bending mold should take into account the space for rotation of the blank during bending, and should not hinder and prevent the blank from moving and rotating, otherwise, it will affect the shape and size of the workpiece. This is particularly important for the shape of complex multi-angle bending.

15. Bending workpiece should not be used for small modulus of elasticity material

The size of the bending springback is proportional to the modulus of elasticity of the material. Materials with a small modulus of elasticity have a large elastic recovery after deformation and are not suitable for bending processes.

The same yield point of the material, the modulus of elasticity of the material after deformation of the elastic recovery is small.

Has been annealed low carbon steel than soft manganese brass suitable for bending workpiece material.

16. Bending workpiece should not be used for high-yield point material

The size of the bending rebound and the material yield limit is proportional. The yield point of high material, after the deformation of the elastic recovery, is larger, and should not be used for the bending process.

That is, the modulus of elasticity of the same material, the yield point of high material, and elastic recovery are larger. Therefore, cold-hardened steel is not suitable for bending processes.

17. For the bending radius and arc angle are very large bending parts, should not use the ordinary bending method

The bending radius and radian angle are very large bending pieces that should be used to roll bending (roll plate), and can not use in the ordinary bending method. Roll bending is placed on the slab in 2 to 4 rolls through, with the rolls of the rotary, so that the slab is bent into shape.

In addition, because the position of the rollers can be properly changed relative to the slab, it can also be made into quadrilateral, oval, and other non-circular sections of the barrel-shaped pieces.

18. Long strip material bending is not suitable for ordinary bending methods

Long strip material around the longitudinal axis of the bending should be used to roll forming and should not use the ordinary bending method. Roll forming is placing the strip in front of and behind the straight row of several sets of forming rollers through. As the rollers rotate, the strip is fed forward and bent into shape in the axial direction at the same time.

Roll forming can produce parts with complex cross-sectional shapes. The rollers are simpler, cheaper and have a longer life.

19. Variable cross-section parts should not use the general roll-forming method

Variable cross-section slotted parts in small and medium-sized production, in order to reduce investment, can be used to roll forming. At this time, in addition to the longitudinal relative movement of the forming roller to the slab, but also transverse imitation movement.

20. Bending of tubes and profiles should not be done by ordinary bending methods

Although the nature of deformation, pipe, profile bending, and sheet bending are the same, the process method and the difficulty of a large difference. Bending of pipes and profiles must be prevented from bending deformation in the rough section shape distortion.

In production, the pipe and profile bending methods are pull bending, rolling, push bending, and bending around. It should be noted that in the convex die of pulling bending, rolling bending rollers, pushing bending, and bending around the fixed die, the working surface should be made to match the shape of the blank section groove to prevent the rotation of the section and the shape of the distortion.

If necessary, a corresponding mandrel should be added to the tube.

Deep drawing

Deep drawing, also known as drawing, etc., is the use of molds, that will get a certain shape after punching flat blank stamping into a variety of open hollow parts or open hollow blank to reduce the diameter, increasing the height of a mechanical processing process.

With the deep drawing, the process can be manufactured into a cylinder, step-shaped, conical, spherical, box-shaped, and other irregularly shaped thin-walled parts. With flanging, expansion, flaring, shrinkage, and other stamping and forming processes, it is also possible to manufacture parts of extremely complex shapes.

Therefore, in the production process of automobiles, aircraft, tractors, electrical appliances, instruments, electronics, and other industrial sectors, the deep drawing process occupies a fairly important position.

Deep drawing process taboos of stamping die design guidelines

1. The relative thickness of the deep-drawn blanks should not be less than 2

The relative thickness of the deep-drawing blank t/D×100, where t is the thickness of the blank, and D is the diameter of the blank. In order to prevent wrinkling, the relative thickness should not be less than 1.5, generally more than 2. In this way, the material stability is good, and not easy to wrinkle.

2. Deep drawing process should not ignore the crimping circle

The deep drawing process is not allowed to wrinkle, so deep drawing work should not ignore the role of the crimping circles, especially for the height of the large and small thickness of the parts.

It is difficult for the blank to pass through the convex and concave mold gap and enter the concave mold after wrinkling, and it is easy for the blank to break with excessive tension, even if it is barely pulled into the concave mold, the surface quality of the workpiece and the life of the mold will be reduced.

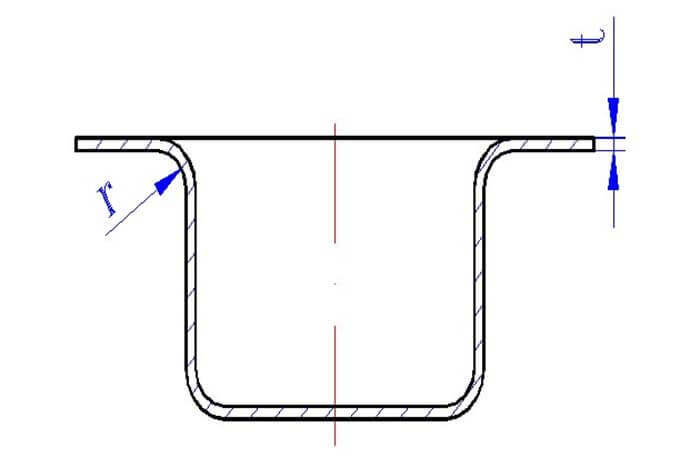

3. The radius of the inner fillet between the bottom and the wall of the drawn part shall not be less than the thickness of the plate

Deep-drawing pieces between the bottom and the wall of the internal angle r should not be less than the thickness of the plate t. From the perspective of favorable deformation, it is best to take:

r=(3~5)t

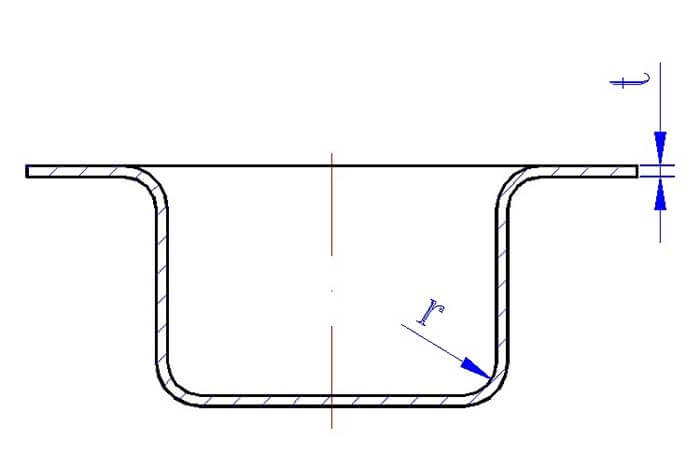

4. The radius of the fillet between the flange of the drawn part and the wall should not be less than 2 times the thickness of the plate

The radius of the corner between the flange and the wall of the deep-drawing part should not be less than 2 times the thickness of the plate. From the viewpoint of favorable deformation, it is best to take:

r=(4~8)t

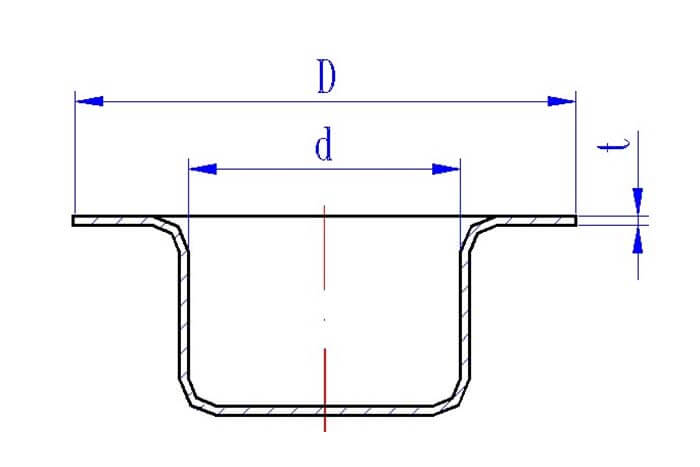

5. The flange diameter of cylindrical parts with flanges should not be too small

In order to press the edge circle in deep drawing can press the slab, so that it is not wrinkled, with the flange of the cylindrical pieces of the flange diameter D should not be too small. It is best to take:

D ≥ d + 12t

The d is the inner diameter of the cylindrical piece.

t is the thickness of the plate.

6. The internal rounding of the corners of the rectangular box should not be too small

To prevent sidewall rupture, the inner corner of the rectangular box should not be too small. It is best to take r>3t

The r is the radius of the inner corner of the corner.

t is the plate thickness.

If r is too small, the material passes through the rounded corners of the concave die, and after repeated bending, the sidewalls become excessively thin and easily ruptured.

7. The ratio of the radius of the inner corner of the rectangular box to the height of the box should not be too small

In order to reduce the drawing coefficient, the ratio between the radius of the inner corner of the rectangular box and the height of the box should not be too small. Generally, take:

r ≥ 1 5H

The r is the radius of the inner corner of the corner.

H is the box height.

8. The drawing factor cannot be ignored when developing a deep drawing process

In order to make the material in the deep drawing stress neither exceeds the strength limit nor can make full use of the plasticity of the material, so that each deep drawing process achieves the maximum possible degree of material deformation, the development process can not ignore the drawing coefficient.

The cylindrical part’s deep drawing coefficient is each deep drawing after the diameter of the cylinder (diameter) and before the elongation of the rough diameter of the ratio. Without flange cylindrical parts of the first deepening coefficient for m1 = d1 / D.

The second deepening factor is m2 = d2/ d1.

The D is the diameter of the blank.

d1 is the diameter of the workpiece after the first drawing.

d2 is the diameter of the workpiece after the second drawing.

9. Deep drawing factor cannot be too small

Deep drawing factor is a coefficient less than 1, the smaller the value, the greater the degree of deformation, and the possibility of damage increases. The deep drawing coefficient is too small, the radial tensile stress in the deformation zone increases and the axial tensile stress in the force transfer zone of the blank side wall also increases.

Therefore, in the development of the deep drawing process, the drawing coefficient cannot be too small. The first deep drawing coefficient m1 can not be less than 0.48, and after each time can not be less than 0.73.

10. Deep drawing factor should not be too large

The drawing factor is the ratio of the diameter of the part after the production of deep and the diameter of the blank before the drawing, which reflects the degree of deformation of the drawing. The deep drawing coefficient is large, the degree of deformation is small, and the number of deep drawings is increased.

To reduce the number of processes, usually use the smallest possible drawing coefficient. There are many factors affecting the drawing coefficient. Generally, the first drawing coefficient m1= 0.48~0.63, after each drawing coefficient is taken as mn=0.73~0.88.

11. Calculation of deep-drawing piece blank size can not ignore the trimming allowance

Due to the uneven radius and clearance of the convex and concave die and the uneven surface finish and lubrication of the working part of the concave die, the wall height of the rotating body workpiece after the deep drawing is inconsistent.

Therefore, the calculation of deep drawing of the blank size, in addition to the principle of volume invariance, so that the cross-sectional area of the blank and the cross-sectional area of the parts after deep drawing equal, can not ignore the trimming allowance. Generally, take 3% to 10% of the height of the deep-drawing parts (small height to take a large value).

12. The first drawing factor of a flanged barrel must not be used when drawing a flanged barrel

With the flange of the barrel-shaped parts of the first deep drawing, the flange part is not all transformed to the wall, and the first deep drawing makes the diameter of the flange reach the diameter of the flange of the parts required.

Therefore, the first deepening of a flanged barrel cannot be done with the first deepening coefficient of a flangeless barrel.

m ≠ d/D. The drawing coefficient of the cylindrical parts with flange is expressed by the following formula.

m=1/

The D is the diameter of the blank.

d is the middle diameter of the shaped part.

df is the diameter of the flange.

r is the radius of the rounded corner.

13. Stepped parts with a height to minimum diameter ratio of more than 0.7 cannot be deep-drawn in one operation

Stepped parts of deep drawing, the deformation process is basically the same as the cylindrical parts of deep drawing. When the total height of the stepped parts and the minimum diameter of the ratio is greater than 0.7 or so, can not be a deep-drawing forming, the need for multiple deep-drawing.

The general number of deep drawings is equal to the number of steps. If the ratio of the diameters of the two adjacent steps is too small (dn/dn-1< 0.73), the cylindrical parts are drawn according to the method.

14. Shallow tapered parts cannot be formed by normal deep drawing methods

Height H ≤ (0.25 ~ 0.3) d shallow conical parts (d for the diameter of the big end), due to the degree of deformation is not large, after the deep drawing due to rebound can not maintain the precise shape of the parts, so can not use the general method of deep drawing, but with a convex rib of the concave die for deep drawing.

Also available rubber or liquid instead of convex die for deep drawing, the effect is better.

15. Deep tapered parts cannot be deep-drawn at once

Deep conical parts with a height of >0.8 d cannot be deep-drawn at once and need to be deep-drawn several times. The most common method is to gradually increase the height of the cone.

16. The gap between the convex and concave die should not be too large when drawing without crimping

When the crimping circle is not used for deep drawing, the gap between the convex and concave die should not be too large considering the possible wrinkling of the material, generally, the gap on one side should be equal to 1 to 1.1 times the upper limit of the plate thickness. The smaller values of the gap are used for the final drawing or for the drawing of precise parts.

z/2 = (1 to 1.1)t

The z/2 is the one-sided gap.

t is the thickness of the sheet.

17. The clearance of the convex and concave die should not be uniform when drawing a rectangular box

When drawing a rectangular box, the gap between the convex and concave die should not be uniform because the material has a stacking phenomenon in the four rounded parts, which makes the corners thicker.

The clearance at the four corners should be 0.1t greater than the clearance at the straight edge (t is the plate thickness). The increased clearance in the rounded corners can be obtained by increasing the size of the concave die or reducing the size of the convex die.

18. The corner radius of the deep-drawing die should not be too small

To prevent scratches or cracks in the deep-drawn parts, the radius of the die should not be too small, otherwise the resistance to the material being pulled into the die increases. The first deep-drawing concave die radius can be selected according to the following table.

Deep drawing way | Relative thickness of blank t/D×100 | ||

≤2.0~1.0 | <1.0~0.3 | <0.3~0.1 | |

Without flange | (4~6) t | (6~8) t | (8~12) t |

With flange | (6~12) t | (10~15) t | (15~20) t |

Note: In the table, t is the thickness of the sheet; D is the diameter of the blank.

The radius of the concave die fillet should be gradually reduced at each subsequent drawing, the relationship is as follows

rn=(0.6~0.8)rn-1

where rn-1 is the radius of the concave die corner of this deep drawing.

rn for the next deep drawing of the concave die radius.

19. The corner radius of the deep-drawing die should not be too large

To prevent wrinkling, the radius of the corner of the deep-drawing die should not be too large, otherwise, the area of the pressed blank under the crimped circle will be reduced, which will increase the overhanging section and make it easy to wrinkle.

20. The radius of the corner of the deep-drawing die should not be too small

To prevent the workpiece from being pulled off, the radius of the corner of the deep-drawing die should not be too small. Generally selected according to the formula.

The first deep drawing: r = (0.7 ~ 1.0) r`

The last deep drawing: r = R (the radius of the inner corner of the part)

Middle drawing depth: r = (dn-1-dn-2t)/2

The r is the radius of the rounded corners of the deep-drawn convex die.

r` is the radius of the rounded corners of the deep-drawn concave die.

R is the radius of the inner corner of the part.

dn-1 is the diameter of the nth deep-drawing cylinder body.

dn is the diameter of the nth deep-drawing cylinder.

t is the thickness of the sheet.

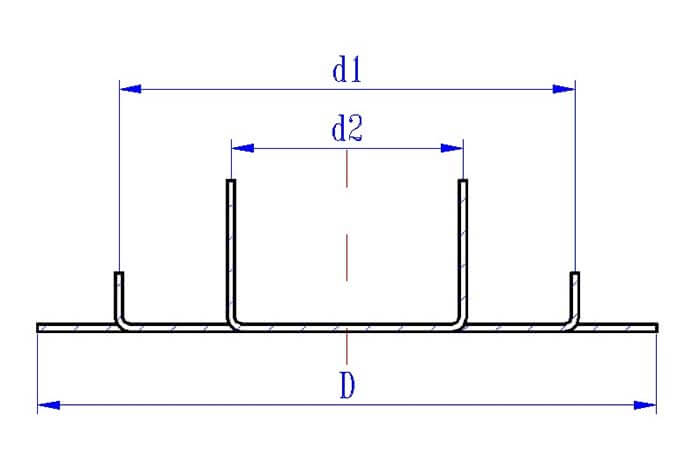

21. The general crimping ring should not be used for deep-drawn parts with thin material and wide flanges

To maintain the balance of the crimping force and prevent the crimping ring from pressing the blank too tightly, it is not advisable to use the general crimping ring for the drawing parts with thin flange width but to use the crimping ring with a limit device, usually take:

s =1.2t

The s is the limiting distance.

t is the thickness of the sheet.

22. Continuous deep-drawing strips should not be made of materials with large cold work hardening

Materials selection principles of stamping die design guidelines

In production, tubes, and profiles are bent by drawing, rolling, pushing, and bending. It is important to note that the convex die of drawing bending, roll bending, push bending, and bending around the fixed die, its working surface should be made to match the shape of the blank section of the groove to prevent the rotation of the section and the shape of the distortion. If necessary, the tube should also be added to the corresponding mandrel.

What are the principles for the selection of materials for stamping dies?

Stamping dies material selection principle:

Reasonable according to its working condition, force conditions and the performance of the processed material, production volume and productivity, and other factors, the selection of die materials and the implementation of the correct heat treatment process is the key to ensure the life of the die.

The selection of materials for stamping dies is crucial, as it directly determines the final quality of the product. The common taboos for the use of stamping materials are summarised as follows.

1. The blanking process should not use brittle or hard materials

For blanking, falling, and edge-cutting processes, brittle and hard materials should not be used. The more brittle the material, the more likely it is to tear in the punching process.

Materials that are too hard, such as high-carbon steel, have a large flatness in the president’s section, which is particularly serious for blanking thick materials.

Materials with good elasticity and high flow limits give good cross-sections. In particular, soft materials such as low-zinc brass can be blanked out with smooth and minimally inclined sections.

2. Highly elastic materials are not suitable for the bending process

The bending process should not use highly elastic materials. The greater the elasticity of the material, the greater the rebound of the formed part to the original state after bending, resulting in the failure of the workpiece to achieve the intended shape, the need for multiple mold trials, and mold repair.

Bending process materials should have sufficient plasticity, lower yield point, and higher modulus of elasticity. The former is to ensure that no cracking and the latter is to make the workpiece easy to achieve the exact shape.

The most suitable materials for bending are low-carbon steel, pure copper, and pure aluminum.

3. Deep drawing process should not be used poor plasticity of the material

The deep drawing process is not suitable for the use of plastic poor materials. The result of low plasticity materials allows the degree of deformation to be small, and the need to increase the number of the deep drawing process and intermediate annealing. Deep-drawing materials require high plasticity, low yield point, and good stability.

The smaller the ratio of yield point and tensile strength of the deep-drawing material, the better the deep-drawing performance, and the greater the limit of a deformation.

Commonly used in deep-drawing materials are low-carbon steel, low zinc brass, pure aluminum and aluminum alloy, and austenitic stainless steel.

4. Cold extrusion processes should not use high strength, low plasticity materials

The cold extrusion process should not use high mechanical strength, and low plasticity of the material, so as not to increase the deformation resistance and produce cracks. Cold extrusion requires materials with high plasticity, low yield point, and low work-hardening sensitivity.

The most suitable materials are pure aluminum and aluminum alloys, brass, tin-phosphor bronze, nickel, zinc and zinc-cadmium alloys, low carbon steel, etc.

Besides the Stamping Die Design Guidelines, 75 Taboos And Rules article, you may also be interested in the below.

Mechanical Design Steps and 525 Taboos

6 Common Plastic Injection Molding Process Techniques

What is Multi-material Injection Molding?

How to Increase the Brightness of ABS Plastic Products?

Hot Runner Injection Molding Defects and Troubleshooting