This article shows the 7 considerations for selecting and applying a hot runner system for injection molding.

To eliminate or reduce the failure in use as much as possible, the following matters should be noted when selecting and applying a hot runner system for injection molding.

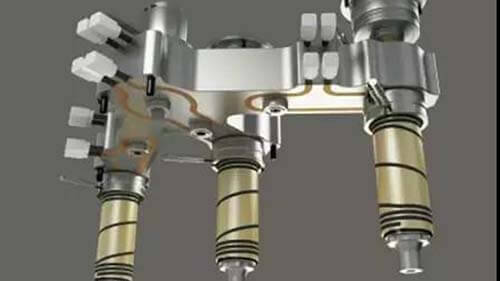

1. The choice of hot runner system heating method

Internal heating method: internal heating nozzle structure is more complex, has a high cost, is difficult to replace parts, and has high requirements for electric heating elements.

The heater is placed in the middle of the runner, producing a circular flow and increasing the friction area of the capacitor. The pressure drop maybe three times as much as the external heat nozzle.

Because the internal heating element is located in the torpedo body inside the nozzle, all the heat is supplied to the material, so the heat loss is small and can save electricity.

If a pointed gate is used, the tip of the torpedo body is kept in the center of the gate, which facilitates the cutting off of the gate after injection and lowers the residual stress of the plastic part due to the late condensation of the gate.

External heating method: The external heating nozzle can eliminate the cold film and reduce the pressure loss.

At the same time, due to its simple structure, easy processing, and thermocouple installed in the middle of the nozzle so that the temperature control is accurate, etc., it is now commonly used in production.

But the external heat nozzle heat loss is larger and less energy-efficient than the internal heat nozzle.

2. The choice of a hot runner system gate form

The design and selection of the hot runner system gate directly affect the quality of plastic parts.

In the application of the hot runner system, the suitable gate form should be selected according to the flowability of resin, molding temperature and product quality requirements, in order to prevent salivation, dripping, leakage, and poor color change.

3. Hot runner system temperature control method

After the hot runner system gate form is determined, the control of melt temperature fluctuation will play a key role in the quality of plastic parts.

Often, the scorching, degradation, or blockage of the hot runner system is caused by improper temperature control, especially for heat-sensitive plastics, which require a rapid and accurate response to temperature fluctuations.

For this reason, the heating element should be reasonably set to prevent local overheating, to ensure that the gap between the heating element and the runner plate or nozzle minimizes heat loss, and should try to choose a more advanced electronic temperature controller to meet the temperature control requirements.

4. The temperature and pressure balance calculation of each manifold

The purpose of the hot runner system is to inject the hot plastic from the nozzle of the injection molding machine, pass through the hot runner system with the same temperature and distribute the melt to each gate of the mold with balanced pressure.

Calculation of nozzle and gate sleeve center offset due to thermal expansion. This means that the centerline of the hot (expanding) nozzle and the cold (non-expanding) gate sleeve should be aligned accurately.

5. Hot runner system heat loss calculation

The internally heated runner is surrounded and supported by the cooled mold sleeve, so the heat loss due to heat radiation and direct contact (conduction) should be calculated as accurately as possible, otherwise, the actual runner diameter will be smaller due to the thickening of the condensation layer on the runner wall.

6. Installation of the hot runner system plate

Both the thermal insulation and the injection pressure should be fully considered.

Usually set up pads and supports between the runner plate and the template, which on the one hand can withstand the injection pressure, in order to avoid deformation of the runner plate and the phenomenon of material leakage, on the other hand, can also reduce heat loss.

7. Hot runner system maintenance

Regular preventive maintenance of hot runner components is very important for the hot runner mold. This work includes electrical testing, sealing components, connecting wire inspection, and cleaning components’ dirty work.

Besides the 7 Notes For Hot Runner System Injection Molding article, you may also be interested in the below.

6 Common Plastic Injection Molding Process Techniques

What is Multi-material Injection Molding?

How to Increase the Brightness of ABS Plastic Products?

Hot Runner Injection Molding Defects and Troubleshooting

11 Analyses of Injection Molding Process Parameters

17 Injection Molding Problems And Solutions