Description

What are the 10L Precision Water Flow Regulators for Injection Molding?

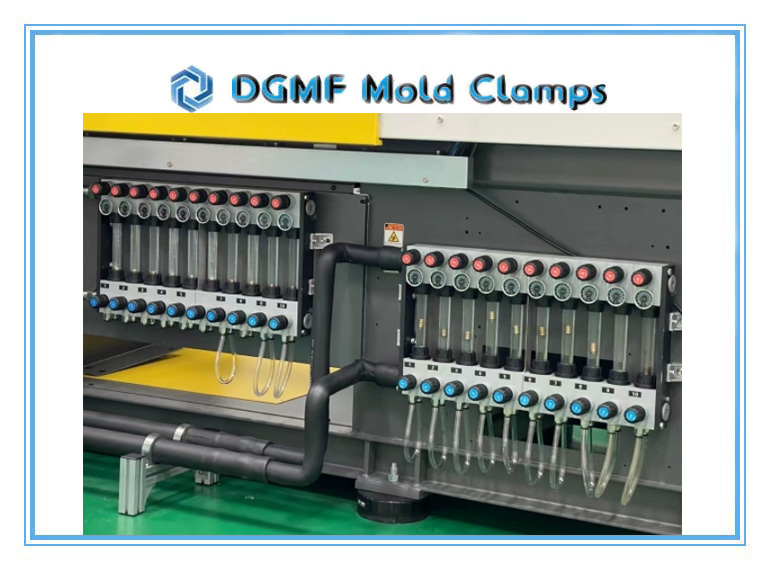

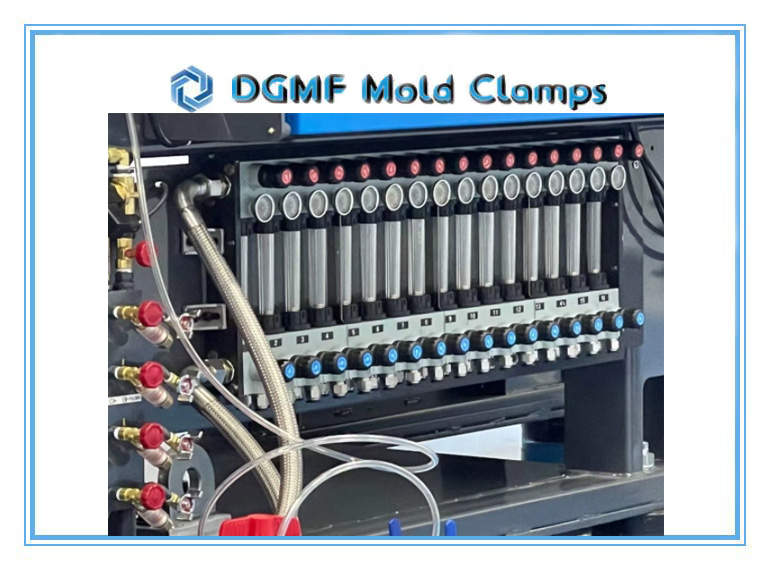

The 10L Precision Water Flow Regulators for Injection Molding DGMF-MOLD-CLAMP-SLT-10L model is a high-precision 0-10-lifer flowmeter, and rotameter supplied by DGMF Mold Clamps Co., Ltd. These precision water flow regulators have a unique design that makes them ideal for working with water chillers, mold heathers, and cooling towers.

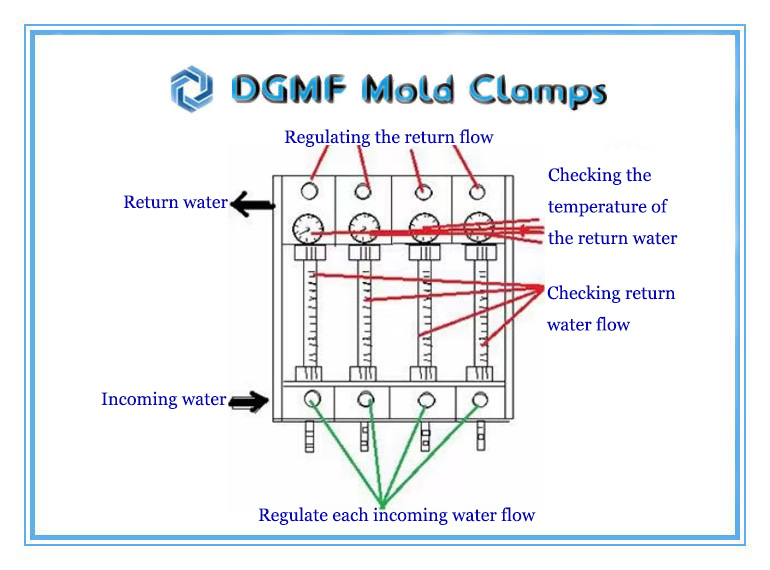

The flow rate of each circuit of the SLT-10L 10L precision water flow regulator is 0-10 liters/minute. It is easy to clean. Adjustable, external sight glass tube rings show deviation, and allow fast flow settings when restarting molds.

The 10L precision water flow regulator is suitable for various injection molding machines and blow molding machines. It can still accurately reflect the water flow rate and temperature of each circuit of the current mold under high and low flow conditions.

The regulating valve is used to adjust the optimal flow rate and production temperature and is marked with an indicator ring for the next production.

Besides the 10L high-precision water flow regulators, DGMF Mold Clamps Co., Ltd also provides the 30L high-precision water flow regulators for your choice. Click HERE for more details.

DGMF 10L Precision Water Flow Regulators for Injection Molding Descriptions

Name: 10L Precision Water Flow Regulator

Material:

Valve body: PA

Circulating pipe: PA

Valve core: Brass

Seal ring: NBR

Technical parameters

Working medium: Water and gas

Temperature: 0~80°C

Pressure: Max.8bar

DGMF 10L Precision Water Flow Regulators for Injection Molding Features

1. Simple design

2. Copper control valve, corrosion-resistant

3. Each part has a thermometer to accurately control the temperature of each pipeline of the mold

4. Transparent tube is convenient for disassembly and cleaning

5. The water flow regulator 10L can be freely combined according to actual needs

DGMF Mold Clamps Co., Ltd supplies mold clamps, injection mold components, machine tools, hopper dryers, and accessories. We are dedicated to offering cost-effective 10L and 30L precision water flow regulators for your choice.

Contact us for more details on the high-precision water flow regulator.

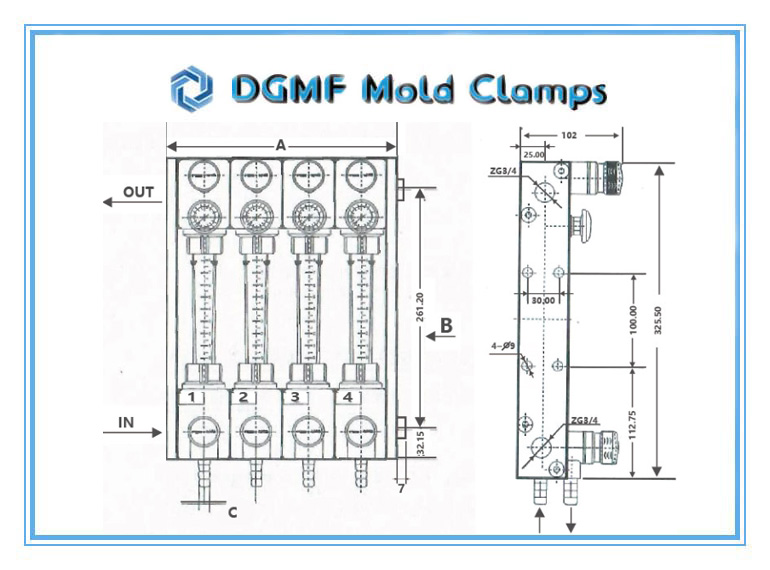

DGMF 10L Precision Water Flow Regulators for Injection Molding Specifications

| Model | Thermometer | Size(MM) | Q’ty of In-and-Outs |

| DGMF-MOLD-CLAMP-SYT-10L-003-T | Yes | 322*190*102 | 3 In-and-Outs |

| DGMF-MOLD-CLAMP-SYT-10L-004-T | Yes | 322*244*102 | 4 In-and-Outs |

| DGMF-MOLD-CLAMP-SYT-10L-005-T | Yes | 322*298*102 | 5 In-and-Outs |

| DGMF-MOLD-CLAMP-SYT-10L-006-T | Yes | 322*352*102 | 6 In-and-Outs |

| DGMF-MOLD-CLAMP-SYT-10L-008-T | Yes | 322*460*102 | 8 In-and-Outs |

| DGMF-MOLD-CLAMP-SYT-10L-010-T | Yes | 322*568*102 | 10 In-and-Outs |

| DGMF-MOLD-CLAMP-SYT-10L-012-T | Yes | 322*676*102 | 12 In-and-Outs |

DGMF 10L Precision Water Flow Regulators for Injection Molding Advantages

(1) Convenient and quick control of coolant temperature, used for mold temperature control of metal die-casting machines and plastic molding machines, so that the product size accuracy is higher, the surface is more shiny, and the forming time is shortened, the mold life is extended, and the production efficiency is improved.

(2) Used for mechanical equipment cooling and lubrication diversion to avoid damage to components due to lubrication out of control and excessive temperature, to achieve the purpose of low-consumption and high-efficiency production.

(3) In pneumatic machinery, the airflow can be adjusted to free the cylinder from problems such as inertial creep and unstable speed.

Detailed of Each Spec of 10L Precision Water Flow Regulators for Injection Molding

How to choose the right water flow regulator specification?

Water Flow Regulator Spec Selections |

|

Water flow regulator flow rate range |

|

| Corresponding number | Description |

| 010 | Water flow rate range 0-10L/min |

| 030 | Water flow rate range 0-30L/min |

| Total water inlet and outlet connector size | |

| Corresponding number | Description |

| A | G 3/4″ Connector |

| B | G 1″ Connector |

| C | G 1 1/4″ Connector |

Water flow regulator tube quantity |

|

| Corresponding number | Description |

| 01 | 1 Tube |

| 02 | 2 Tubes |

| 04 | 4 Tubes |

| 06 | 6 Tubes |

| 08 | 8 Tubes |

| 10 | 10 Tubes |

| 12 | 12 Tubes |

Water in-and-out hose connector size |

|

| Corresponding number | Description |

| 0 | No connector |

| 1 | 12mm connector |

| 2 | 13mm connector |

| 3 | 14mm connector |

| 4 | 20mm connector |

| 5 | Customized |

Thermometer |

|

| Corresponding number | Description |

| N | Without a thermometer |

| T | With a thermometer |

| Total inlet and outlet connector mounting | |

| Corresponding number | Description |

| R | The G connector on the water flow Regulator’s right side |

| L | The G connector on the water flow Regulator’s Left side |

DGMF 10L Precision Water Flow Regulators for Injection Molding Workflow Diagram

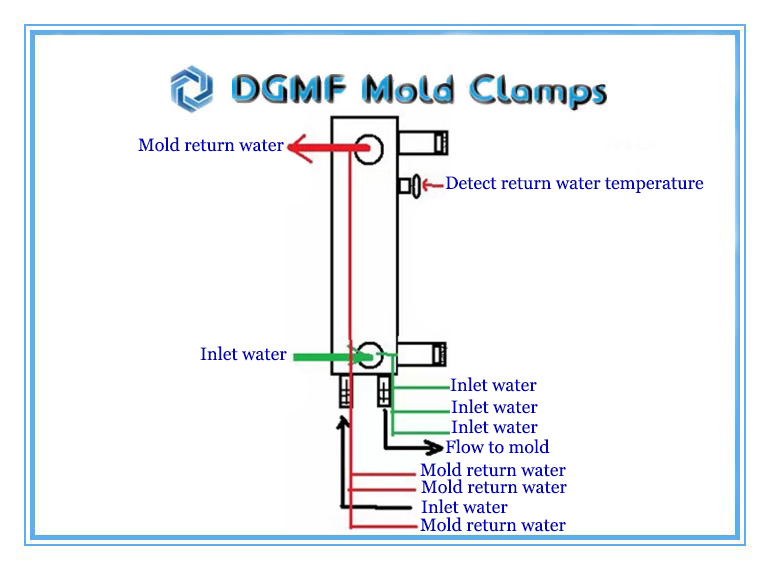

The circulating water enters the mold through regulating valve 1. After the circulating water circulates in the mold, it is adjusted and enters the transparent cylinder through regulating valve 2.

The size of the water flow can be read through the float scale. The thermometer displays the temperature of the water flowing through the pipeline.

The circulating water then returns to the mold temperature controller, ice machine, or cooling tower through the outlet.

DGMF Plastic Injection Molding 10L Precision Water Flow Regulator Breakdown

Don’t hesitate to contact our DGMF sales team for the ones you are looking for.

DGMF 10L Precision Water Flow Regulators for Injection Molding Applications

Application range:

1. Used for mechanical equipment cooling and lubrication diversion, which can easily control the outflow of fluid.

2. On pneumatic machinery, the airflow can be adjusted.

DGMF 10L Precision Water Flow Regulators for Injection Molding Cleaning:

Circulation water flow regulator pipe cleaning method

1. Turn off the water supply

2. Use a special tool to open the perspective pipe nut, remove the perspective pipe nut and the pipe together, and then pull the pipe out of the perspective pipe nut.

3. Use a pipe brush to clean the pipe

4. Replace (repair) the O-ring on the screw cover

5. Reassemble in the reverse order of the above

DGMF 10L Precision Water Flow Regulators for Injection Molding Package